The role of beliefs in accident prevention.

Many organizations believe that occupational accidents and resulting injuries are caused by some short coming on the part of the individual worker.

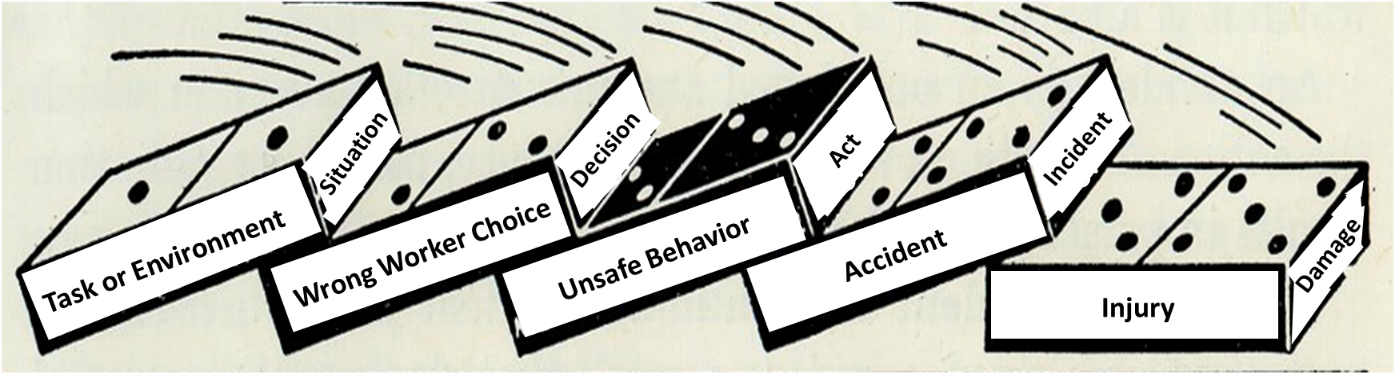

The Domino Effect Theory of accident causation proposed by HW Heinrich may explain the justification for this.

Preventable injuries culminate from a series of sequential events, as represented by five dominos.

The first represents the task or situation, followed by some faulty worker decision, resulting in the unsafe action, which leads to an accident and the inevitable injury.

By tipping the first domino all tend to fall, and by removing some of the intervening dominos the accident can be eliminated.

Hence the belief that workers' decisions or actions are the primary cause of accidents.

The findings of two major research studies supported this conclusion.

The first by Heinrich in 1931 where he analyzed over seventy thousand accidents.

He found that:

- 88 percent of injuries resulted from actions of employees;

- 10 percent of the accidents were traced to hazards involving the physical environment;

- 2 percent of the accident’s cause could not be ascertained.

- The even larger one by FE Bird in 1966 which analyzed over 1.7 million accident reports from hundreds of companies and concluded that:

- 95 percent of injuries resulted from actions of employees;

- 5 percent of the accidents were traced to causes from the physical environment.

These studies confirmed that most accidents were caused by some action by the worker thereby focusing intervention on changing their action or behaviors in order to reduce and eliminate accidents.

Beliefs regarding accident causation

Accident causation may be affected by beliefs associated with:

- Individual factors (age, experience, personality, motivation, perception, needs, expectations, etc.),

- Social factors (lifestyle, family issues, education, economic status, etc.)

- Cognitive factors (understanding, reasoning, comprehension, insight, intelligence, etc.)

- Circumstantial factors (perceived work relationship with supervisor or peers, degree of perceived exposure, job security, etc.)

- Organizational factors (e.g., culture, climate, management's attitude, group norms, etc.)

In many industries but especially construction, all people involved—from the organization’s workers through to executives; and partners in the supply chain have some understanding of the existence of worksite risks, but have different opinions as to how this results in accidents and injuries as well as how to best deal with this reality.

This thinking (belief or bias) fundamentally impacts the way risk and safety are evaluated, addressed and the effectiveness of preventive measures devised and deployed.

Supervision factors

The same accident may be attributed to various factors stemming from different beliefs about accident causation as held by different people (foremen, superintendents, managers, experts, safety practitioners, etc.) working on the job site.

Prevailing wisdom attributes the cause of the accident to the decision made or behavior engaged in by the worker.

This may include such things as inattention, inexperience, lack of focus, rushing, carelessness, fatigue, complacency, ignorance, not using common sense, failure to follow good work practices, or even downright stupidity to name a few.

The worker may take risk for convenience, or due to happenstance.

These biases may be motivated or driven by one's belief system, one's position in the organization, or possible involvement in causation, to name a few.

This posture and ultimate goal are defensive in nature.

The positions of those involved will become more entrenched and will be greatly affected by the seriousness of the accident and the ultimate potential outcome of the situation.

Worker factors

The reasons given for accidents by workers provide a window into their attitudes and beliefs about safety, accident causation, or the confidence they have in their ability to deal with hazardous work situations.

The worker involved in the accident may attribute the cause of the accident to operational factors, such as the need to rush in order to meet production goals, maybe the unavailability of proper tools or equipment or their condition, and a lack of protective measures or equipment, little or no concern for safety.

On the worker's part, risk taking may be associated with confidence in their ability to deal with the risks involved due to past experience, confidence in their skills, underestimating the level of the risk, or the degree of exposure.

Workers who need the work will generally accept a higher level of risk, work in environments that are more hazardous, and use tools that may be inappropriate for the task, in order to meet perceived or actual expectations.

Or they may simply attribute the accident to bad luck.

Systems factors

Another way to look at the basic Domino Effect Theory is to look at the first domino (task or environment) and make a determination as to why the risk existed in the first place and whether it could have been eliminated or its negative impact diminished; prior to assigning the task to the worker.

This is probably the most effective approach to eliminating accidents or reducing their adverse effects.

This step involves the person responsible for planning, directing, executing, and/or controlling the work.

The next question involves the second domino and a determination should be made as to why the worker decided to proceed in the way that they did which led to the accident and the resulting injury.

This requires understanding whether the worker identified the risk, was able to determine its significance, the degree of exposure, have the capability to perform the task, etc.

This requires the appreciation and understanding that systems (policies, practices, and procedures) may create situations that allow risk to enter into the work process and may be the primary source of risk in the work environment.

Conclusion

Beliefs involving the impact of risk on the worker's safety and the perceived benefit of risk taking should be a factor that is assessed when considering or evaluating the motivation underlying the resulting behavior.

Depending on the situation, beliefs can positively or negatively affect safety and its management.

Beliefs about control are important to accident analysis and the explanations of causation.

By gaining insight into such beliefs and taking those into account, accidents may be analyzed more realistically, and robust preventive measures can be devised and implemented.

The importance that beliefs play in workplace safety and its management has been identified in numerous research studies.

Researchers have also verified that subjective judgment by people is a major component in any risk assessment.

If such judgment is faulty, the risk management process and efforts will, in all likelihood, be misdirected and garner inferior or no beneficial results.

It has been asserted that in reality, much of accident preventive measures are driven by causal inferences rather than the actual drivers of such events.

Product Feature: Models

We have an extensive line of die cast scale models available for forklifts, mobile elevating work platforms, loaders and excavators.

Each equipment model is made using heavy die cast with working components, realistic exterior and interior detailing.

Available for CAT, Clark, Toyota, JLG, Bobcat, Genie, and BT brands.

Also available, our CASTLE Multi-function Model to help demonstrate capacity, stability and leverage to your operators.

These die cast training aids are a terrific visual for every trainer to use as a training aid in their operator class.

Click to browse or purchase our

Models.

Incident Report: Maine contractor faces $501k in fines.

A Maine roofing and siding contractor faces $501,000 in fines after federal safety inspectors reportedly found employees working 10 to 18 feet above ground without guardrails, safety nets, or other safeguards.

Inspectors also found the contractor failed to train those employees properly.

Andrew Raymond Pollock of ARP Renovation and A.R.P. Roofing & Siding

willfully exposed at least five employees to falls while working on multiple occasions in October and November 2021 at the Oak Knoll Village Condos on Victoria Way in Hampden, the U.S. Department of Labor said Thursday.

According to a release, after the DOL's Occupational Safety and Health Administration notified Pollock of the fall protection requirement, he refused to correct the hazard, and OSHA posted notice of imminent danger at the site and has proposed $501,376 in penalties.

Pollock was also cited for violations of requirements to provide employees with training programs about fall hazards and ladder safety, ensuring ladder side-rails are extended 3 feet above the upper landing surface, ensuring employees wear head protection when working below roofing operations and maintaining OSHA illness and injury records.

“Every employee working without fall protection at the Hampden jobsite was exposed to potentially deadly or disabling falls, despite Mr. Pollock’s knowledge that this safeguard was required and necessary,” OSHA Regional Administrator Galen Blanton said in the release.

“How dangerous is working without fall protection? Falls are the leading cause of death in construction work in the U.S., the Bureau of Labor Statistics reports.

In 2020, falls accounted for more than one-third of all construction fatalities nationwide.

These fatalities can be prevented if employers follow safety standards to protect their workers from known hazards."

Pollock was cited for fall-related hazards at New Jersey worksites in 2014 and 2021, according to the release.

ARP Renovation and A.R.P. Roofing & Siding have 15 business days from receipt of the citations and penalties to comply, request a conference, or contest the findings.

Source:

News Center Maine

Ask Bob

Free technical support for all IVES Certified Trainers!

Question:

Hi Bob!

We sent an employee to the Train the Trainer session for Premium Forklift which included Narrow Aisle Forklift.

Our employee is indicating that even though he has completed the Train the Trainer, he is not certified to operate the equipment himself.

When someone attends a Train the Trainer program, are they deemed competent to operate the equipment after completing the program?

We do not have another Narrow Aisle Trainer on site to put him through the training program so we are wondering how best to proceed.

Answer:

Thanks for checking in with us.

Unfortunately, no, completion of the IVES Train the Trainer program does not deem him as competent to operate the equipment.

The main reason is that a practical evaluation needs to be conducted on the operator in the workplace where they use the equipment.

Also, and equally as unfortunate, a trainer cannot evaluate themselves as most regulatory authorities would not consider it to be an objective evaluation.

On a positive note, your trainer did receive the required, basic theory training during the program, so all you would need to do is to provide additional, site specific (company safety polices/procedures etc) training and have another trainer conduct a practical evaluation of your trainer.

If you do not have another trainer available, you will need to call in a 3rd party trainer to conduct the evaluation of your trainer on your equipment at your site.

I wish there was a way around this, but since the evaluation needs to be site specific, we are unable to ‘certify trainers as operators’ at our open enrollment programs.

With that in mind, be weary of any 3rd party that claims they can evaluate your trainer off site and send him back to you as a competent operator as this would not be compliant with federal or state OSHA regulations.

Bob

Interesting Articles

- Iowa man dies after being struck by excavator [VIDEO]...more.

- Boomlift becomes impaled on railroad bridge...more.

- Bird chirping to protect her eggs from Excavator [VIDEO]...more.

- Man killed in forklift crash is remembered...more.

- Crane operator runs for his life as silo collapses the wrong way [VIDEO]...more.

- Forklift incident led to facility fire in Kansas...more.

- Man steals forklift, leads deputies on a slow-speed chase [VIDEO]...more.

Client Testimonials

"Amazing program, so much to learn, but the expertise of the trainer helped me to thoroughly learn all the material." Paul, Premium Forklift Train the Trainer Program.

"This was probably one of the best training classes I’ve ever had. I would definitely recommend this class to anyone." D'Wayne, Premium Combo Train the Trainer Program.

"Even though we were on Zoom, I found it very easy to follow. I did like that I was able to take this online and not have to travel in order to be in a classroom setting." Kevin, Online Trainer Recertification Program.