The IVES Update Newsletter is a highly informative monthly e-newsletter. It contains up-to-date industry information, regulatory updates, stories from the field, upcoming program dates, What’s Wrong With This? photos, incident reports, our interactive “Ask Bob” question and answer column, new product details and much more.

Whether you're interested in forklifts, mobile elevating work platforms, loaders or excavators – we’ve got you covered. Want to receive it directly to your inbox? Sign up for our IVES Update e-Newsletter!

Year:

Most businesses face the possibility of worker accidents and potential injuries. In all likelihood, they have a safety department or an assigned person to oversee and manage such possible outcomes. Traditionally the management of safety involved complying with the company safety program. The bulk of the program pretty much regurgitated the safety standards as promulgated by the relevant State or Federal jurisdiction. Some organizations may add additional requirements to this program based on specific risks, past experience, or other relevant considerations.

Most businesses face the possibility of worker accidents and potential injuries. In all likelihood, they have a safety department or an assigned person to oversee and manage such possible outcomes. Traditionally the management of safety involved complying with the company safety program. The bulk of the program pretty much regurgitated the safety standards as promulgated by the relevant State or Federal jurisdiction. Some organizations may add additional requirements to this program based on specific risks, past experience, or other relevant considerations.

There were two significant governmental legislation which impacted the approach to occupational accidents and the associated attention and management of worker injuries. The first was the enactment of workers compensation legislation by various states starting in 1911 with the last one adopting it in 1948. This brought about some level of improvement in worker safety. But the need for greater uniformity throughout the country as well as further reduction in accidents led to the passage of the Occupational Safety and Health Act by the Federal Government in 1970.

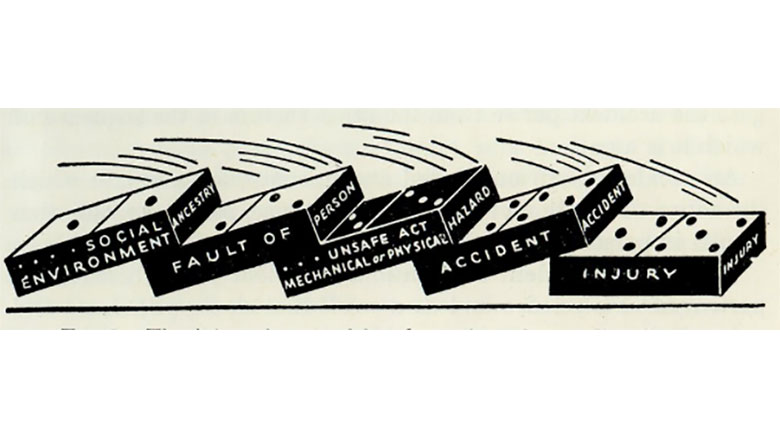

With the passage of the workers compensation legislation, worker accidents and the resulting injuries had financial consequences for their employers. This created the need to understand why workers were getting injured on the job, so as to allow management to intervene in order to reduce the number of accidents and therefore control their related costs. Industry got their answer when H. Heinrich proposed the domino theory of accident causation. The theory proposed that injuries resulted from a number of interrelated and preceding factors.

Heinrich proposed that injuries were the result of a series of events that happened in sequence, and the removal of any one of the preceding events would stop the injury from occurring. He proposed five elements to this series. An occupational example:

Since just about every accident occurs due to some unsafe act on the part of workers, supervisors and management tied to find reason for this. These could be attributed to inattention, rushing, lack of knowledge, carelessness, distraction, unfamiliarity with safety best practices, fatigue, unfamiliarity with the safety program elements, etc. All of which pointed to some form of deficiency or negligence on the part of the worker. The more common approach to dealing with this was to provide safety training to workers, as well as conducting more inspections, in order to address and stop unsafe behavior on the part of the worker.

Image credit: Peter Furst

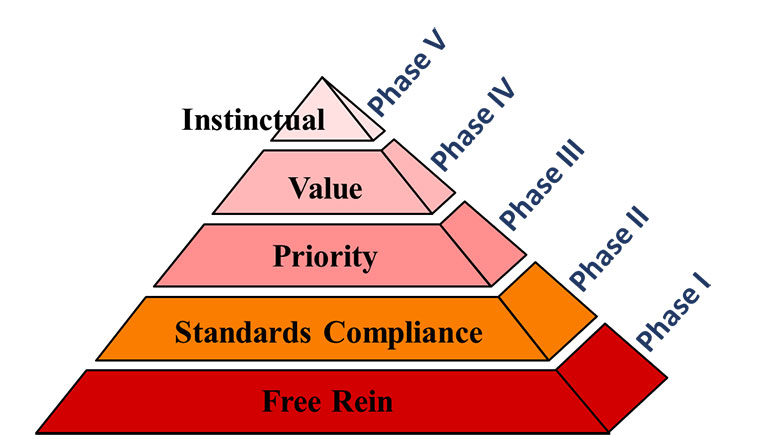

The management of safety evolved over time due to a number of factors (see Figure 2). The industrial revolution created a demand for a large number of workers in factory settings. Those organizations were not terribly concerned with worker safety (see my articles “Challenges in safety management: History & program issues” and “A Look into Safety Management”) as it was deemed that worker were responsible for their own safety and wellbeing.

With the passage of the Occupational Safety and Health Act, organizations were required to comply with safety standards and report results. The frequency of certain accidents or the annual risk evaluation of safety outcomes with a broker or insurance carrier caused the safety function of the organization to make certain program element a priority in order to try to control similar accidents from occurring. Forward thinking organizations through leadership and management were able to make safety a value which not only reduced the risk of injuries but reduced their severity and to some extent, controlled cost. The implementation of the five pillars will make safety instinctual and will more effectively make accidents somewhat rare events.

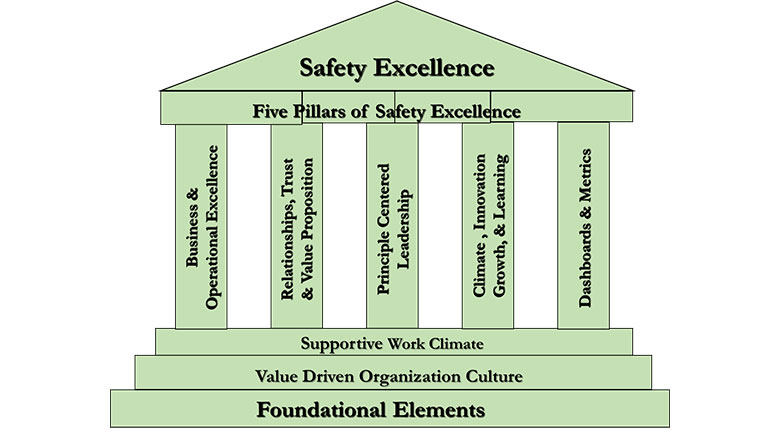

Starting with a solid foundation (see Figure 3), the five pillars will support continued excellence in operations as well as provide a framework for achieving excellence in workforce safety. Foundationally the organizational systems, polices, procedures and practices must be integrated and aligned in order to support effective operations. The value proposition must exceed customer and partner expectations and build trustful and loyal relationships, leadership must create a supportive work environment which reduces risk, and enables worker performance, success and job satisfaction.

There has to be a robust value-based culture that fosters nurtures, supports, rewards, and values, safe operations. There exists a positive leader-member exchange, with organizational justice, mutual trust and respect, along with excellent communication fostering cooperation which results in efficient and effective operations. In a value-based organizational culture, everyone leads from core principles, contributes to safe operations, is involved and champions the safety and health of all involved. This will, and should, make safety processes, procedures and practices instinctual.

Image credit: Peter Furst

The five pillars provide the framework that creates an innovative, excellence driven, business focused approach to addressing challenges and fostering the implementation of a robust safety management process. This then results in the achievement of excellence in safety outcomes.

Business and operational integration is crucial to the creation of efficient and effective systems which allow for, and support an injury-free workplace. The internal systems, processes, and procedures must be in harmony, aligned, and all working towards the creation of a risk and injury-free workplace. This internal alignment drives a 360-focus horizontally, vertically and inside to outside the organizational approach. The outside factor involves the value chain partners, vendors and suppliers. They need to be in alignment with the organization’s systems in order to further excellence in all aspects of the business, it also impels partners to cooperate, delivering on their promises with flawless execution. This reduces risk to its lowest possible level and supports the safety and health of all workers.

In many industries there is a long value chain populated by a number of independent organizations, all of whom have to ensure the achievement of common interest objectives by cooperating in order to accomplish their common goals. They have to make sure they deliver on their promises in order to build trust. Trust is critical in every business exchange and a key factor in influencing behavior. Organizations may need to clearly present their value proposition which should stress fair treatment, ethical behavior, cooperative problem solving, etc. in order to build effective, harmonious, interdependent, trusting relationships. Trust could play a key role in the management of safe operations as well as to foster the safe behavior of involved individuals.

Leadership is a key element in creating and sustaining a value-based organizational culture, which supports and fosters excellence. Principle focused leadership involves creating a positive, enabling, and satisfying work environment, ethically behavior, inspiring a shared vision, innovating thinking, enabling and encouraging followers to engage, challenge the process, fostering learning and growth, modeling the way, as well as leading positive change. It also means creating an open, safe, trusting and empathic work environment based on a positive leader-member exchange creating a superlative work climate leading to a safe and healthy worksite.

Innovation, growth & learning are important because of the nature of modern business. Just about the only constant in business is that change is inevitable, and change is occurring at ever faster rates. So, the organization has to understand its environment and learn from it so as to change its internal processes and procedures, foster growth and remain competitive. The innovation continuum includes efficiency, evolutionary, and revolutionary innovation. Growth involves increased knowledge and understanding of the employees thereby enabling them to effectively operate, and support the internal integration and alignment necessary to create the injury-free workplace.

To effectively manage you need to measure, senior management understands that the measurement system influences organizational behavior. Effective measurement has to be predictive as well as prescriptive in nature if it is to provide information for managing performance. Another thing that contributes to difficulty or complexity is that often important factors tend to be hard to measure consistently and objectively.

The scorecard also serves to bring together into one report several important but seemingly diverse aspect of the business. Another important aspect of the organizational scorecard is that it creates a platform for alignment within the organization. This is important to strategy deployment, as well as guarding against sub-optimization. A robust scorecard represents all the important operational measures holistically.

Excellence in safety can only be achieved through a strategy-driven, performance-based safety management process, supported by operational excellence, driven by principle centered leadership, sustained by engaged and involved employees, and facilitated by a value-based culture. Obviously, we need to approach the process holistically. Safety should be fully integrated into the organization’s operations, and safety outcomes should be aligned with business goals. Therefore, the safety process will become woven into the very fabric of the organization, become instinctual, and achieve an injury-free workplace, which will naturally flow from the operational activities.

A council has been fined £200,000 after an employee was injured while putting up the town’s Christmas tree.

A council has been fined £200,000 after an employee was injured while putting up the town’s Christmas tree.

James Lyth, who worked for Bury Council, was using a scissor lift to straighten the 20-foot tall Christmas tree when it toppled over with him still in the basket.

The tree was being installed by an external company at Bury Market on 21 November 2022 when the accident happened.

The 32-year-old operations manager suffered concussion and severe injuries to his right-hand side, including bruising to his ribs.

He needed an operation to his leg and was left using a wheelchair and crutches after sustaining a large cut to his leg.

Mr Lyth was off work for two months and was subsequently only able to return on restricted hours and duties as he continued his recovery.

An investigation by the Health and Safety Executive (HSE) found that Bury Metropolitan Borough Council had failed to provide Mr Lyth with any training in the safe operation of the scissor lift and had failed carry out a sufficient risk assessment for this work activity.

The investigation also found that a suitable risk assessment of the work would have identified the dangers involved and the need to restrict the use of scissor lifts to those with appropriate training.

Bury Council pleaded guilty to breaching the Health and Safety at Work Act and was fined £200,000 and ordered to pay costs.

HSE inspector Leanne Ratcliffe said: “This was a very serious incident.

“It is important for industry to understand the importance of a risk assessment and training when using elevated platforms.

"Access to these platforms should be limited to those trained and anyone who isn’t trained shouldn’t be allowed to use them.

“If this sort of work is not planned and controlled to a high degree, then there is a very high likelihood of a potentially fatal fall, or one resulting in very serious injury.”

Source: itvNews April 2025

Q: Do I need to have a written test if am re-evaluating an employee or is the re-evaluation sufficient?

Q: Do I need to have a written test if am re-evaluating an employee or is the re-evaluation sufficient?

A: Thanks for checking in with Ask Bob.

Technically, the CALOSHA requirements are to conduct (at minimum) an evaluation of each operators performance every 3 years.

It has been my experience that if that is all I do, a large percentage of operators will fail the evaluation due to a few small bad habits that lead to their demise.

I have found that if I use the requalification packages (8 study guides and 1 notepad) and conduct a quick refresher training using the study guides as a group exercise, administer the requalification theory test and then conduct a bit of hands-on training to break any bad habits (if any) and then conduct the re-evaluations, I have an almost 100% success rate.

When adding up all the time it takes to re-train and then re-evaluate (again) the failed operators, I am far ahead if I follow the IVES suggested lesson plan for requalifications.

"Honestly, I have nothing but good things to say about the program. I learned a lot, and I think the company is going to improve a lot!"

"Honestly, I have nothing but good things to say about the program. I learned a lot, and I think the company is going to improve a lot!"

Gabriel R, Custom Train the Trainer Program

"This is by far the best Forklift/MEWP training and instructor training I’ve ever been a part of – Thank you!"

Jeff O, Premium Combo Train the Trainer Program

"The training was excellent. I feel confident in my new ability to train operators to abide by the highest safety standards."

Kojin F, Premium Forklift Train the Trainer Program

copyright © IVES Training Group 2022 All Rights Reserved.