The IVES Update Newsletter is a highly informative monthly e-newsletter. It contains up-to-date industry information, regulatory updates, stories from the field, upcoming program dates, What’s Wrong With This? photos, incident reports, our interactive “Ask Bob” question and answer column, new product details and much more.

Whether you're interested in forklifts, mobile elevating work platforms, loaders or excavators – we’ve got you covered. Want to receive it directly to your inbox? Sign up for our IVES Update e-Newsletter!

Year:

Health and Safety training has a reputation problem. Most often, it’s repetitive and isn’t retained by the audience yet we continue doing the same thing repeatedly, expecting different results. Let’s flip the script. We need to rethink how we design and deliver training to improve long-term retention and change perceptions of safety bringing only a compliance-driven value.

The problem with traditional training is that it’s too often treated as a compliance-driven “check the box.” Compliance is essential, but it doesn’t have to be boring. Too many times I’ve sat through the same slides, the same photos — some of them dating back to the 80s and 90s, and felt my engagement drop immediately. Outdated content signals to the audience that the message is old and irrelevant.

When training turns into “death by PowerPoint,” it strips away ownership. Trainees don’t feel like they have any skin in the game, and without that, retention and application outside the classroom simply don’t happen. Throughout my career, I’ve seen plenty of workers “pass” a training, walk back onto the floor, and fall into the same unsafe habits we had just discussed. That is a clear signal: it’s not the workers failing the training — it’s the training failing the workers. We have an opportunity, and a responsibility, to deliver training that achieves sustainable results, not just a signed roster.

We all have a library of health and safety training we’ve leaned on over the years. But when was the last time you really updated yours? Too often we recycle the same content year after year to meet requirements and “check the box,” just so everyone can get back on the floor. That may satisfy compliance, but it doesn’t drive retention — and it certainly doesn’t change behavior.

This is where we need to challenge ourselves to flip the script: make training more engaging, not more complicated. Several years ago, I renewed my fall protection competent person training alongside a group of PIT operators. The facility had a recurring problem: employees weren’t donning harnesses correctly, and harnesses were being left dangling from order pickers during breaks. The training explicitly covered these issues — yet it was so painfully dull that most people tuned out.

Everyone “passed” the training that day. But the very next morning, as I walked the floor, I saw the exact same unsafe practices. That moment reinforced for me that the issue wasn’t lack of knowledge — it was lack of retention. Training that doesn’t stick is training that fails.

Training should be engaging, relevant, and memorable. That means adopting approaches that fit the times and the workforce we’re serving. The most impactful training solutions are never one-size-fits-all. They need to reflect the industry, the facility, and the audience. Over the years, I’ve found several methods that consistently deliver stronger results.

Short, digestible sessions in the form of micro-learnings are a great way to keep attention and reinforce key points. These quick hits work especially well for general awareness or refreshers. For example, a five-minute module on ladder safety or a quick reminder about hazard reporting before a shift can make a lasting impact. The key is that micro-learnings support retention, but they don’t replace the need for comprehensive, role-specific training.

For high-risk work, blended training has been a game-changer. This approach combines classroom instruction, where you build a strong knowledge foundation, with hands-on practice in the field. I’ve seen this model work best when trainees can immediately apply what they’ve learned. For instance, after classroom instruction on fall protection, moving directly into harness inspections, proper donning, and simulated rescues drives both confidence and competence. Blended training doesn’t just tell workers what safe looks like — it gives them the chance to practice it in real conditions.

Training is not a one-and-done event; it should be a constant work in progress. A scheduled session on a specific topic may be the starting point, but it should never be the end. True retention comes from what happens after the classroom, and this is where we most often fall short.

Reinforcement is key to whether or not learning sticks or doesn’t, and it’s also where leadership support has the greatest impact. When leaders model the behaviors they expect, employees are far more likely to take ownership of safety themselves.

The most effective reinforcement strategies I’ve seen come through peer-to-peer mentoring, behavioral observations, and consistent recognition of positive behaviors. Something as simple as calling out a job well done for a properly tied-off harness, a team that paused to eliminate a trip hazard, or a worker who reported a near miss all reinforce the message that safety is valued. These daily moments of encouragement build a culture where training isn’t just remembered but lived.

Imagine the impact we could have if we all committed to training retention, not just training completion, which is the true goal of training. Instead of checking a box, training could become the catalyst for lasting behavior change. That shift alone would change the trajectory of risk prevention and strengthen a culture of safety ownership.

This isn’t a challenge for one company or one industry sector but rather a call to all of us in health and safety. If each of us updated one training this year, including the design and delivery, we would reinforce learning, and the collective impact would be great.

Training is one of the most powerful tools we have to influence safety culture. Let’s stop repeating what is ineffective and start creating learning experiences that truly stick. The future of safety depends on it.

Source: OHS Nov 2025

As we approach the end of the year, we want to express our heartfelt gratitude to our clients and partners for their unwavering support.

We wish you a joyful holiday season filled with happiness and health.

Please note that our offices will be closed on December 25 and December 26 in observance of the Christmas holiday.

We will also be closed on January 1 for New Years Day.

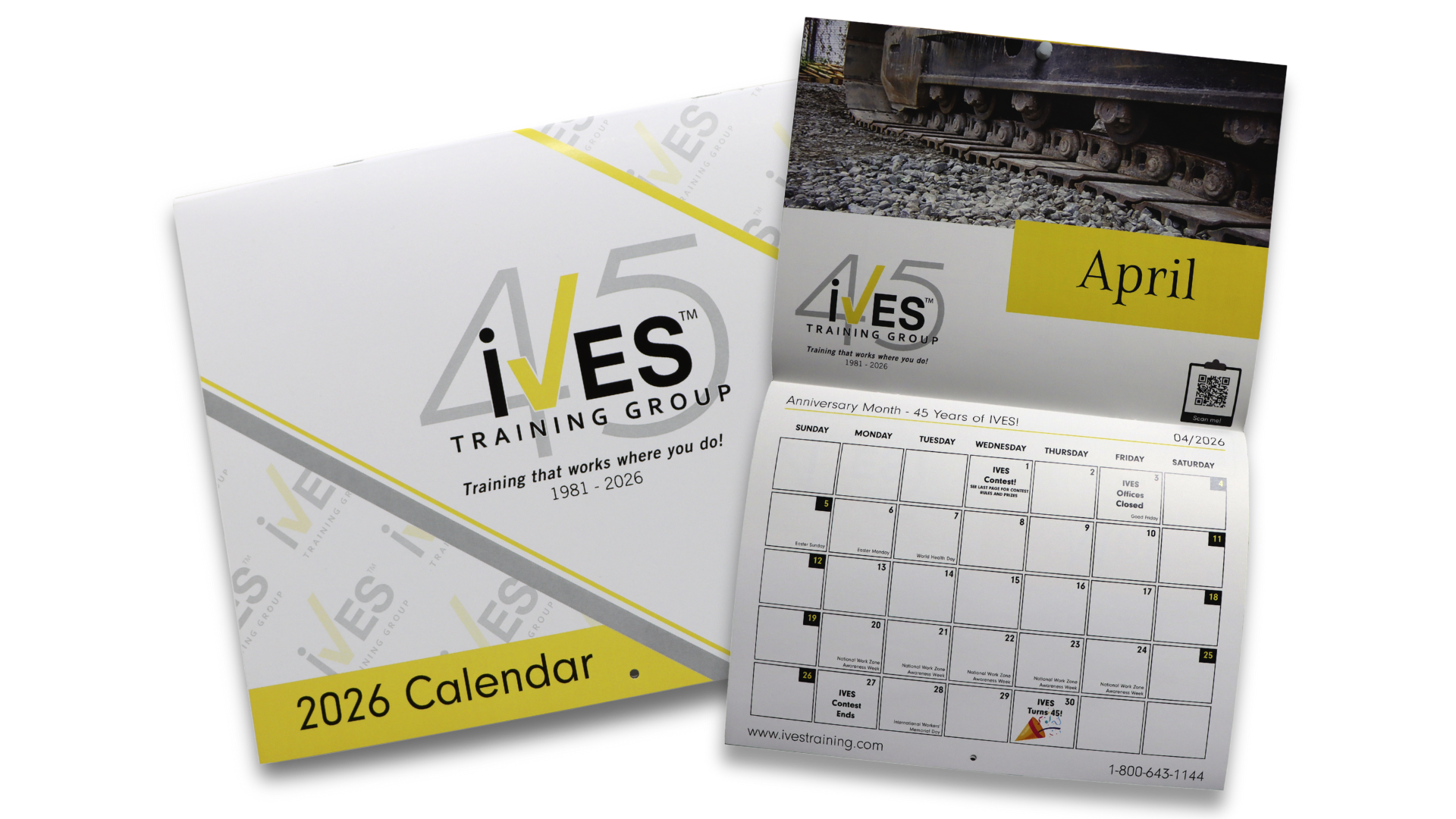

As we look forward to 2026, IVES Training Group is preparing to celebrate its 45th year in business!

Keep an eye on our social media as we will be releasing promotions throughout the year!

We will also be including a commemorative 45-year calendar to all our product orders placed, while supplies last.

A construction company in southwest Washington faces more than $170,000 in state fines after a 3,000-pound excavator bucket detached from an excavator arm and crushed a worker inside a trench, injuring him twice before he was rescued.

A construction company in southwest Washington faces more than $170,000 in state fines after a 3,000-pound excavator bucket detached from an excavator arm and crushed a worker inside a trench, injuring him twice before he was rescued.

According to the Washington State Department of Labor & Industries, the Rotschy Inc. employee was inside a trench box giving hand signals to an excavator operator when the bucket fell, crushing the lower half of his body. As the operator attempted to lift the bucket using the excavator’s hydraulic arm, it slipped again, causing a second crush injury. Firefighters freed the worker, who was hospitalized for more than a month with severe injuries.

L&I’s investigation found that two excavators on the jobsite, including the one involved in the incident, were equipped with quick couplers—devices that allow operators to switch attachments without leaving the cab. Both couplers were missing a required safety latch intended to prevent buckets from falling if an operator makes an error or if equipment fails.

“Quick couplers are standard in the industry, but removing the safety latch from them certainly isn’t,” said Craig Blackwood, assistant director of L&I’s Division of Occupational Safety and Health. “This young man’s life will be forever impacted by this incident that was entirely preventable.”

Supervisors informed inspectors that they were aware the safety latches were missing, and a Rotschy maintenance employee had reported seeing couplers without latches over the past year. When the company inspected all of its excavators after the incident, 13 were found to be missing the required latches.

Investigators also documented other hazards on the Woodland site. There was no walkway for workers to cross the trench safely, and the site supervisor was allowing employees to jump across the 10-foot-deep opening. L&I also found no cave-in protection around an upright sewer manhole located within the trench.

Rotschy was cited for two willful serious, two repeat serious, and two serious violations totaling $170,136. The company is being added to the state’s Severe Violator list, subjecting it to increased oversight.

During the initial response, an inspector also raised concerns about potential confined space hazards. A concurrent inspection resulted in an additional $13,770 in fines issued Nov. 10 for five serious confined space violations tied to the sewer manhole.

L&I classifies violations as serious when they could directly lead to severe injury or death, and as willful when an employer knew or should have known the rules but failed to follow them.

Rotschy is appealing all citations and penalties. Fine revenue is directed to the state’s workers’ compensation supplemental pension fund, which supports injured workers and the families of those killed on the job.

Source: OHS Dec 2025

Q: Hi Bob,

Q: Hi Bob,

Is there a regulation on documentation?

What I mean is if an employer only has copies of the training documents does that meet the requirements?

Does OHSA require the originals?

A: OSHA does not clearly state 'originals' or 'copies' but we always suggest that the employer get all of the original documents of training and the trainer keeps copies to keep everyone happy.

However, as long as there are good copies of all the training records, I do not see it being an issue with OSHA as long as all their regulatory requirements are met:

Under the OSHA regulations (this is in your regulations, under Section L, operator training requirements:

6. Certification: The employer shall certify that each operator has been trained and evaluated as required by this paragraph (l). The certification shall include the name of the operator, the date of the training, the date of the evaluation,

and the identity of the person(s) performing the training or evaluation.

If you are using our documentation process you will have more than the minimum OSHA requirements. That being the case, if things get far enough for lawyers outside of OSHA to get involved, they love original documents.

"The training materials are fantastic. The lesson plans will save me hours of preparation. The course is very thorough"

"The training materials are fantastic. The lesson plans will save me hours of preparation. The course is very thorough"

Seth K, Premium Combo Trainer Certification

"Enjoyed how interactive and I testing (with real world stories/examples the class was presented). Made a dry but important topic easier to learn."

Steven E, Custom Trainer Certification

"This is my fourth training I’ve received in my career. By far this was the most informative and thorough."

Shawn M, Loader Group Trainer Certification

copyright © IVES Training Group 2022 All Rights Reserved.