The IVES Update Newsletter is a highly informative monthly e-newsletter. It contains up-to-date industry information, regulatory updates, stories from the field, upcoming program dates, What’s Wrong With This? photos, incident reports, our interactive “Ask Bob” question and answer column, new product details and much more.

Whether you're interested in forklifts, mobile elevating work platforms, loaders or excavators – we’ve got you covered. Want to receive it directly to your inbox? Sign up for our IVES Update e-Newsletter!

Year:

Please be advised that revisions and additions have been made to our existing operator training materials as follows:

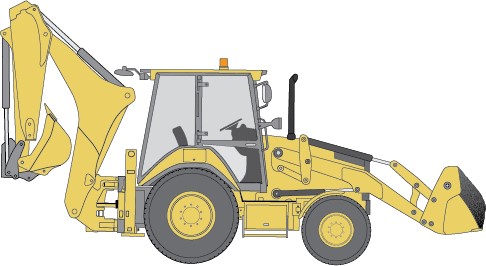

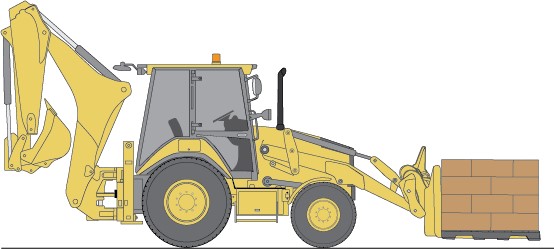

1. Backhoe Loader (formerly Loader Backhoe):

a. The Operator Reference Manual (ORM) - the English language version is completely revised with new, updated information and graphics. Some items to take note of concerning the new ORM are:

i. Its title has changed from, Backhoe Loader to, Loader Backhoe (BHL). This change more accurately reflects today’s common industry language when referencing this type of machine

ii. It specifically addresses backhoe loaders that share the following design features:

1. Equipped with rubber tires filled with air, nitrogen or foam.

2. Designed around a tractor unit to which various work attachments can be connected to the front and rear.

3. Commonly powered by internal combustion engines, usually diesel engines.

4. Typically fitted with material buckets at the front loader section and rear backhoe section, but can be equipped with a variety of work attachments at either end.

BHL equipped with material buckets.

BHL equipped with front pallet forks.

b. The BHL Operator Final Written Test –is updated and now consists of:

i. Twenty questions. A grade of 70% or 14/20 minimum score is required to pass.

c. The BHL Trainer’s Manual Insert (SUP-031) – is now updated with revised answer keys for the questions in the ORM as well as the operator final written test. Qualified trainers may download the revised pages from the IVES website.

d. BHL Operator Digital Training (DTA) – is brand new and loaded with images that match and compliment the text and images in the ORM. Trainers of BHL operators that choose to use this invaluable training aid will add a dimension of colorful, visual accompaniment to their training programs.

e. ORM Chapter Review Indexes (SUP-201-e) – is an extremely useful document provides BHL trainers with a detailed guide listing the correct answers and locations of every chapter review question in the ORM as well as the questions in the operator final written test. More than just an answer key, the indexes within this document not only provide the correct answers to every question, but the exact location(s) of where the supporting information is found in the ORM. Trainers of BHL operators can use this document to familiarize themselves with the new ORM and use it as a reference during training.

f. BHL Operator Lesson Plan (LPO-012) - contains step by step instructions for the delivery of an entire BHL operator training program with an updated information on coverage of the new ORM.

g. New BHL Operator Requalification Materials:

i. The BHL Operator Requalification Study Guide is brand new and matches the new ORM.

ii. The new BHL Operator Requalification Notepad complete with an operator requalification theory test is now available. The test consists of 10 questions with grade of 70% or minimum score of 7/10 required to pass.

h. Orientation Video – a video viewable from the IVES website offering BHL trainers a guided tour of the new materials by an IVES Certified Master Trainer.

i. Downloadable Materials – are available to qualified trainers who log in to the Downloadable Materials & Updates section of the IVES website www.ivestraining.com. These materials include:

i. The answer key to the BHL Operator Final Written Test.

ii. The revised pages of the BHL Trainer’s manual Insert (SUP-031)

iii. The BHL ORM Chapter Review Indexes (SUP-201-e).

iv. The BHL Operator Lesson Plan (LPO-012).

v. Orientation Videos as follows, not for download but available for viewing:

1. BHL ORM & Related Documents

2. BHL Digital Training Aid

3. BHL Requalification Materials

Spanish language versions of the new ORM, DTA, Study Guide and Notepad are also available now!

The employer of a worker who died after being crushed by a forklift at Logan International Airport in August has been cited and fined thousands in penalties in connection with his death.

The employer of a worker who died after being crushed by a forklift at Logan International Airport in August has been cited and fined thousands in penalties in connection with his death.

Oxford Airport Technical Services of Rochester, New York now faces “four serious citations with $46,096 in proposed penalties” for failing to ensure safeguards, the federal Occupational Safety and Health Administration said in a statement on Monday.

“Every workplace fatality is tragic, especially when there are well-known safety measures that could have prevented the loss of a person’s life,” OSHA Area Director James Mulligan said in a statement. “In this case, the employer failed to train and certify their forklift operators on critical safety requirements. It’s simply inexcusable.”

On Aug. 29, 2023, an Oxford Airport Technical Services’ employee was attempting to drive a forklift into a building at Logan Airport when the vehicle’s forks and mast struck the overhang of the entrance, causing the forklift to tip over, according to OSHA. The operator, who was not wearing a seatbelt, fell to the ground, and the tipping vehicle fatally struck him.

OSHA inspectors found that the company failed to ensure the worker wore a seat belt while operating the forklift, exposing him to rollover and crushing hazards. The agency also determined the following:

The forklift’s forks and mast were not raised only as far as necessary to clear the road surface.

All forklift operators were not properly trained and certified.

A damaged forklift was not examined before being placed in service.

A damaged forklift was not taken out of service.

According to OSHA, the man’s death “may have been prevented if his employer, a Rochester, New York-based maintenance firm, had ensured proper safeguards for operating and maintaining forklifts.”

Oxford Airport Technical Services has 15 business days from receipt of its citations and penalties to comply, request an informal conference with OSHA’s area director, or contest the findings before the independent Occupational Safety and Health Review Commission.

Source: Boston 25 News

Safety equipment & accessories are necessary to make sure your operators stay safe and comfortable on the job.

Forklift accessories like weather guards will help protect your forklift operators from the elements.

Also check out our IVES promotional gear including neck lanyard with ID holders, carrying cases and hats!

Q: My company is asking me why we have to fill the propane tank off the forklift and not while the tank is still attached to the forklift.

Q: My company is asking me why we have to fill the propane tank off the forklift and not while the tank is still attached to the forklift.

I remember that this is a violation of a fire code.

Can you help find out where this fire code is or what the reason for this is?

A: You can find the requirements for tank removal in the NFPA standards. NFPA 505: Section 9.1.2.10.

You will also find it stated in most operation manuals as well.

To the best of my knowledge, the reasoning behind removing the cylinder from the truck during refilling is general safety, as removing it ensures the engine is not running and that the operator can’t drive off while filler line is still attached to the cylinder, for example.

"The skills and experience gained throughout will be transferable throughout different employment opportunities and life."

"The skills and experience gained throughout will be transferable throughout different employment opportunities and life."

Brandon, Premium Combo Train the Trainer Certification

"First training course I have attended in a long time that truly engaged me and thoroughly equipped me for becoming a trainer."

Kevin, Loader Group Train the Trainer Certification

"Very well laid out program that at the end, you feel like you have all the tools and guidance to be a good trainer. Very Informative while being fun at the same time."

James, Premium Combo Train the Trainer Certification

copyright © IVES Training Group 2022 All Rights Reserved.