The IVES Update Newsletter is a highly informative monthly e-newsletter. It contains up-to-date industry information, regulatory updates, stories from the field, upcoming program dates, What’s Wrong With This? photos, incident reports, our interactive “Ask Bob” question and answer column, new product details and much more.

Whether you're interested in forklifts, mobile elevating work platforms, loaders or excavators – we’ve got you covered. Want to receive it directly to your inbox? Sign up for our IVES Update e-Newsletter!

Year:

We are very proud to announce that on Friday, September 26 at our open enrollment training center in Abbotsford, B.C., Dustin Wraye of Molson/Coors breweries successfully completed his trainer program and was issued Certified Trainer number 30,000!

“This milestone is more than just a number, it’s a testament to the enduring partnerships, shared commitment to safety, and the incredible individuals like Dustin who carry the IVES legacy forward.” Roneel Shankar, IVES General Manager. Shankar, who was on site at Molson/Coors Chilliwack, BC Division to celebrate the milestone with Dustin and his coworkers showered Dustin with some cool IVES swag including personalized “30K” Certified Trainer hats, a full loaded Power Pack and a commemorative wall plaque inscribed with Dustin’s Certificate of Completion information with that “30,000” CT number prominently displayed. Congratulations Dustin!

It is very fitting that IVES and Molson/Coors, who have been connected through safety for thirty-two years, should reach this milestone together as both companies have worked long and hard to get here. While issuing CT number 30,000 is an IVES achievement, it literally would not have been possible without companies like Molson/Coors and the thousands of other companies who have given their trust and support to IVES over the years. So, congratulations Dustin, Molson/Coors and everyone else for your belief in and commitment to IVES Training Group. Thank you!

Reflections on 30,000

It seems like only yesterday that I was at Blommer Chocolate Co. in California to present one of our newly minted IVES Certified Trainers, with his IVES credentials designating him as our 10,000th trainer. It was quite an event. The folks at Blommer enthusiastically welcomed me and Liz McClatchey, the Director of the Sacramento-based Safety Center Incorporated back then, with whom IVES was and still is thankfully partnered with. They were quite tickled about us making the presentation on-site and even stopped production to gather the entire staff so they could witness the proceedings and share in their co-worker’s moment of recognition. Afterwards, as Liz and I walked through the parking lot back to our cars I remember her saying, “Wow, ten thousand. Quite an accomplishment, you must be very proud.”

I was proud, very proud, but this wasn’t my accomplishment. It took over 20 years to hit the 10K mark and for about 15 of those years, I wasn’t around. A lot of very good people ran themselves ragged to make that happen, I was just the lucky sod that got to make the presentation.

The strange thing is that now, with trainer number 30,000 in the rear-view mirror - yep, I said trainer number 30,000!!!- with me being part of the company from then until now, I feel exactly the same way. Proud, but humble, as still more good people, many of whom I’m sad to say are not with us anymore, toiled and labored selflessly to make it possible for our little company to do such big business.

How big? Allow me to illustrate. If 30,000 IVES trainers decided to go to a concert, we would easily sell out any indoor arena in North America, some for week straight. There are even about 8 outdoor stadiums we could completely fill! If we were part of the army, we would form two full divisions, with “Salus Prima” (Safety First) as our motto. If we all formed a company, we would have more employees than Mitsubishi Motors, Penske Automotive, Wynn Resorts, Central Japan Railway, the National Bank of Canada, and many more. If we all went on a road trip and brought a gallon of gas each, we would get about 750,000 miles down the road! That’s around the globe 30,000 times or to the moon and back two and a half times.

The bottom line is that 30,000 of almost anything is a lot. And although lots of people have worked very hard to get us to this, our most recent plateau, it is all of you that truly made it happen. Without your belief, trust and investment in us, all of our efforts would have come to nothing. So, for giving us the opportunity to blow our horn about reaching number thirty thousand, thanks a million!

Rob Vetter

Director of Training, Owner

IVES Training Group

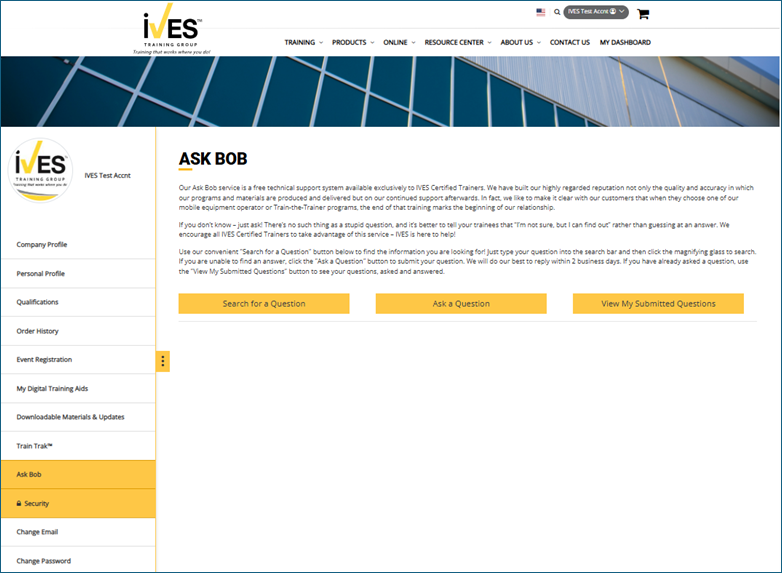

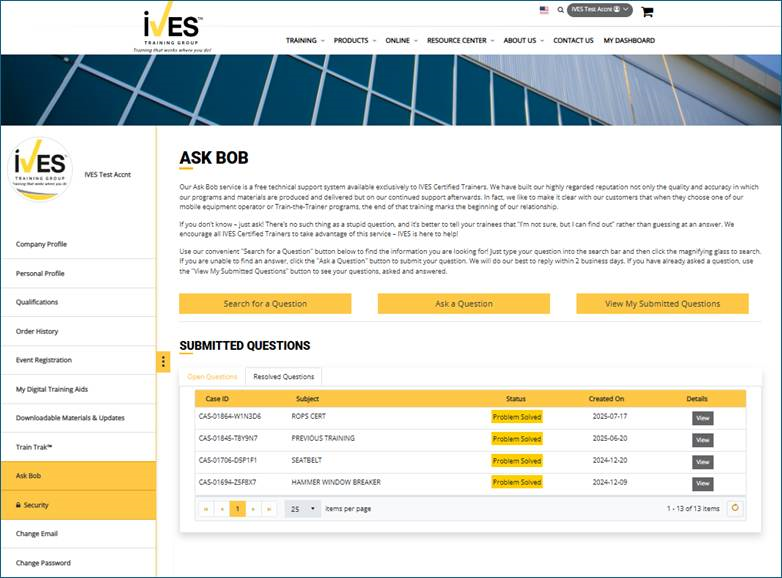

Our Ask Bob trainer resource has been significantly updated with improved functionality and an enhanced user experience.

One of the key changes, apart from a new layout, is that there is no need to search for a question first before you ask one of your own.

Now, when you go to Ask Bob, you have a choice to search for questions that Bob has previously answered, or view questions you’ve submitted, and of course, ask a new question.

We invite you to check out these improvements for yourself and hope you find using Ask Bob for technical support easier and more user-friendly than before.

Below you can see the new layout of the Ask Bob landing page available from your Dashboard.

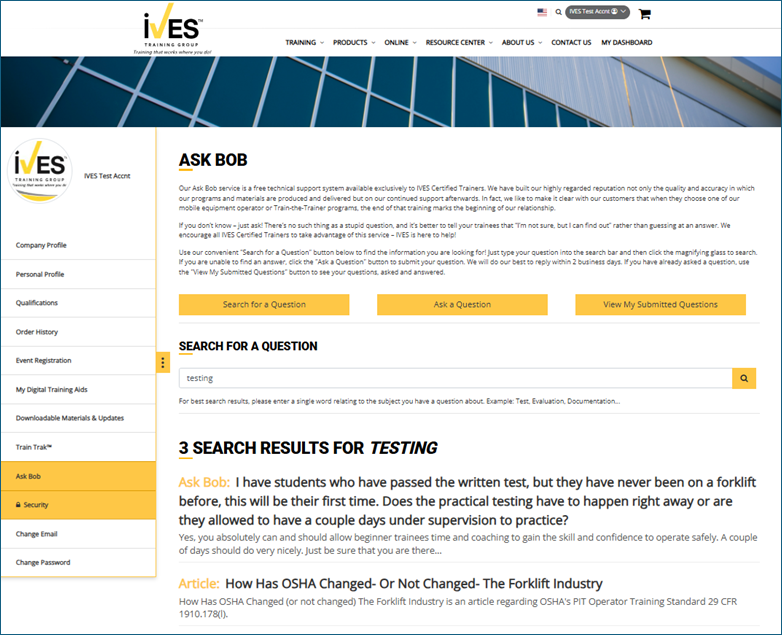

When searching for an answer to your question, you will see that the results are either a question that another trainer has asked and Bob has answered, or a related article that contains pertinent information.

Keeping your search to one or two words will yield the most results.

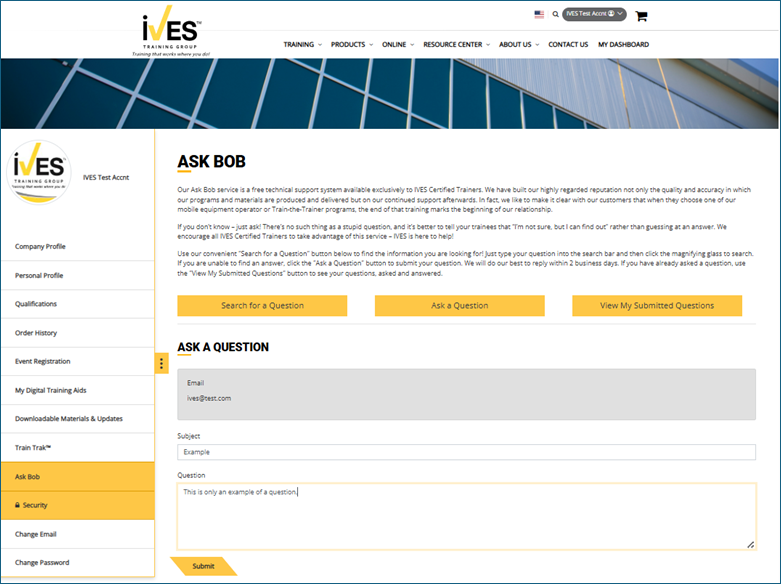

When submitting a question, enter the subject of your question and then the question itself.

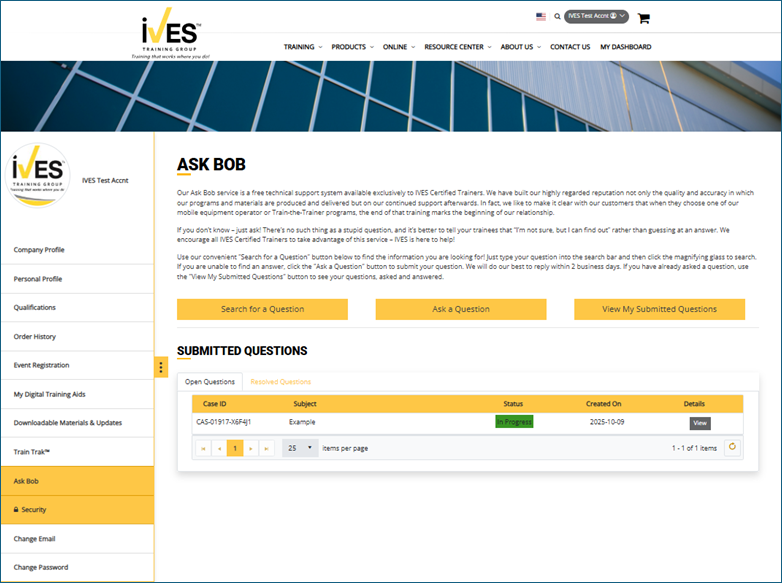

If you have previously submitted questions, you will find them under View My Submitted Questions.

The Open Questions tab will show recent, not yet answered questions, and the Resolved Questions tab will allow you to revisit those which have already been answered.

The Health and Safety Executive (HSE) brought the prosecution following its investigation of the incident involving Harvey Addison, from Ipswich, on 11 December 2023.

The Health and Safety Executive (HSE) brought the prosecution following its investigation of the incident involving Harvey Addison, from Ipswich, on 11 December 2023.

Mr Addison was unloading cars from shipping containers at the company’s site in Ipswich. Working with the driver of the forklift truck to empty two small bins, filled with waste packaging, including ratchet straps and chocks, into a larger commercial waste bin.

The two tipping bins had been positioned on a pallet, which was being carried on the forks of the forklift truck.

The 21-year-old was standing on the pallet and as the forklift truck moved some of the straps fell from the full waste bins, trailing on the floor and getting caught in the wheels of the lift truck. One of these straps got caught on his foot pulling him to the ground and the forklift truck drove over his foot.

Mr Addison remained in hospital for nine days, requiring skin grafts on the outside of his left calf and behind his left thigh just above his knee. He also sustained a broken ankle.

An investigation by HSE identified that Qube Containers Limited failed to provide equipment that was safe and suitable for the task and failed to risk assess the system of work for emptying the bins – which was found to be unsafe.

In addition, the traffic routes were not organised in a safe manner, and it was clear from the work practices on site that vehicles and pedestrians circulated in close proximity.

Qube Containers Limited of Forbes Business Centre, Kempson Way, Bury St Edmunds, Suffolk, pleaded guilty to breaching Section 2(1) of the Health and Safety at Work etc Act 1974. They were fined £30,000 and ordered to pay £3,752 in costs at Norwich Magistrate’s Court on 12 September 2025.

HSE Inspector Adepeju Sogadgi said: “This injury could easily have been prevented. Employers introducing new processes should make sure they assess the work activity sufficiently and apply effective control measures to minimise the risk. There should be systems in place to ensure safety and the risk should have been considered and documented.”

This HSE prosecution was brought by HSE enforcement lawyer Julian White and paralegal officer Hannah Snelling.

Source: HSM September 2025

Q: I

recently conducted forklift training and noticed damage on the seat belt.

Q: I

recently conducted forklift training and noticed damage on the seat belt.

I have been researching what California Code of Regulation or industry standard outlines maintenance and repair requirements and have been unsuccessful thus far.

Could you please point me in the right direction?

A: Thanks for checking in with us.

Seatbelts: OK, as you know, CALOSHA references industry standards for design and construction of forklifts—primarily ANSI/ITSDF B56.1(PIT) and B56.6 (RT forklifts). These are free to download from itsdf.org once you register for free.

I went to the B56.1 standards and then they refer you to B56.11.8 Safety Standard for Seat Belt (Lap-Type) Anchorage Systems for Powered Industrial Trucks. This can also be downloaded from the same site to refer to.

This standard provides the performance and testing requirements for anchorage systems of lap-type belts (seat belts) provided with counterbalanced, center control, high lift trucks that have a sit-down, non-elevating operator.

Now, if this does not cover what you are looking for, for example damage to the webbing or discoloration, then you will have to check the operators manual and the service manual provided by your manufacturer.

You may also find that the manufacturer places an expiration on the seat belts as well in the actual service manual (not typically in the operators manual-fyi)

Just my opinion, but if in doubt, I find it easier to just replace it rather than work through all this to find out that they say if there is any damage to the webbing or discoloration from original color to replace it.

"I thought all the info was very good and material was easy to read and use. I’ve been in a lot of training classes. This class by far is the most informative."

Carey K, Custom Trainer Certification

"There was a lot of information in this class that I never knew – even after operating the forklift over 25 years."

Carrie S, Custom Trainer Certification

"Great handouts, easy to follow and understand. Really good training program! Enjoyed all the information, I learned a lot of practical and useful information."

Ryan G, Premium Combo Trainer Certification

copyright © IVES Training Group 2022 All Rights Reserved.